Non-Destructive Testing (NDT) is crucial for industries that require precise material inspections without causing damage. Ensuring structural integrity is essential for safety, compliance, and operational efficiency.

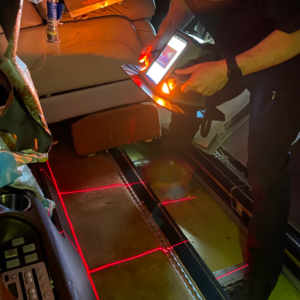

Videray’s cutting-edge PX1, PX Ultra, and PXT handheld X-ray scanners deliver unparalleled imaging clarity, enabling real-time detection of hidden defects, weld inconsistencies, and material flaws. Our Modular Transmission Panel (MTP+) enhances inspection capabilities with dual-imager functionality, providing deeper penetration for even more comprehensive inspections.

Industry Applications & How to Use Videray X-Ray Scanners

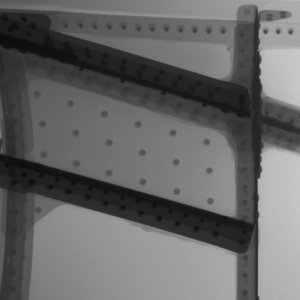

Aerospace & Aviation

Inspect aircraft components, and welds without disassembly, ensuring structural integrity and regulatory compliance.

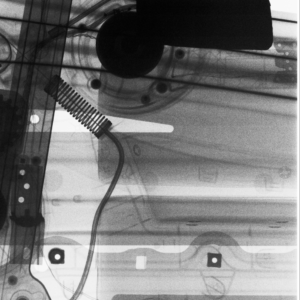

Automotive

Conduct rapid weld inspections, identify corrosion, and evaluate structural integrity in vehicles without dismantling key components

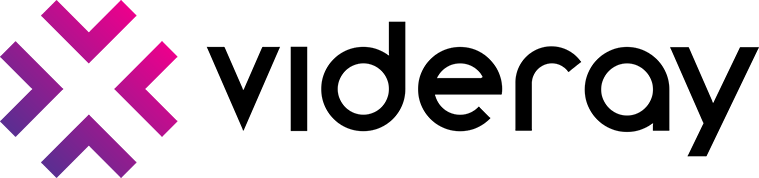

Aircraft structure inspection scan

Infrastructure

Locate rebar positioning, identify corrosion and moisture buildup in pipes, which can lead to structural weakening and long-term damage.

Manufacturing

Detect internal defects in castings, metal structures, and 3D-printed parts to improve product quality and prevent failures.

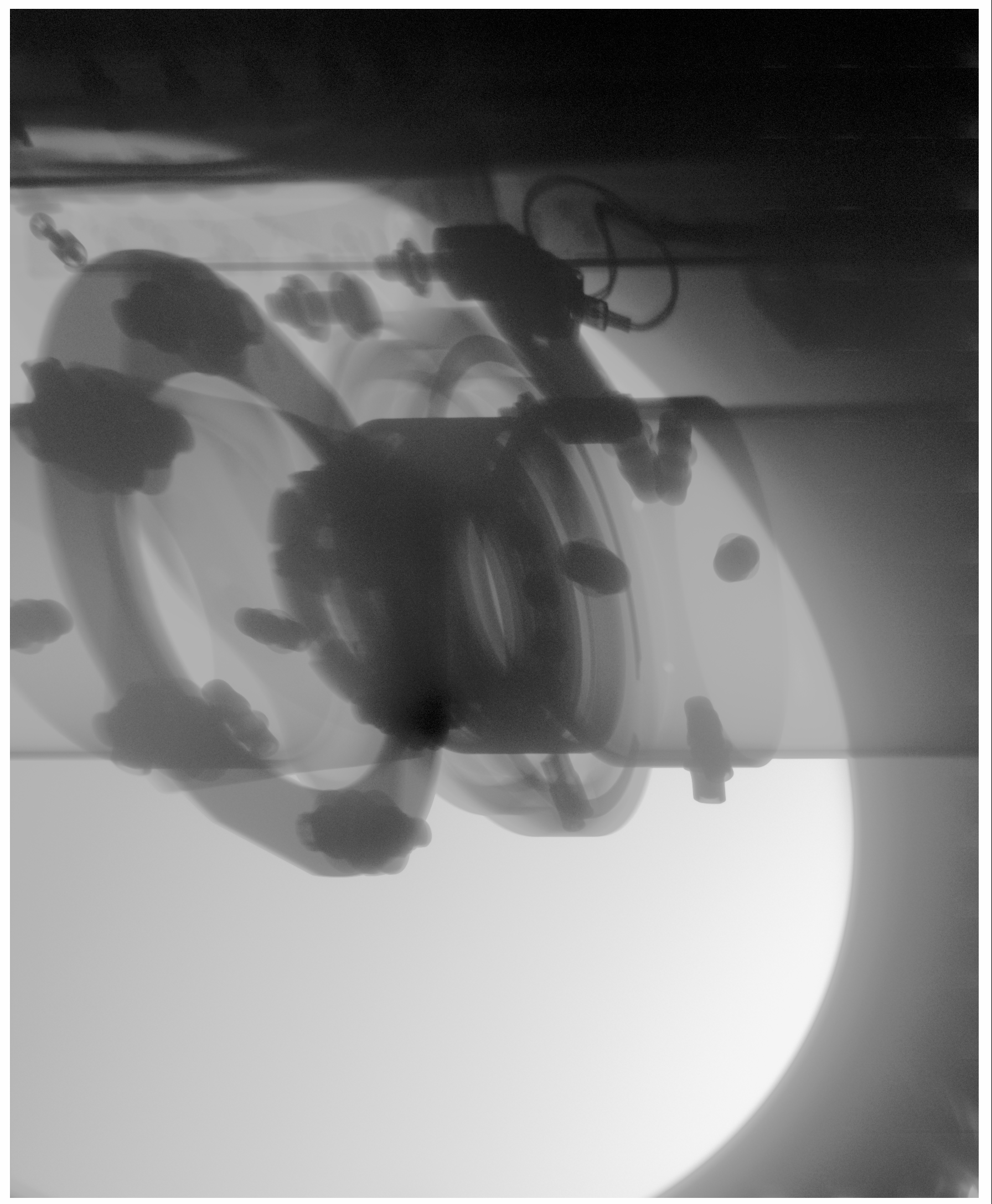

Moisture detected throughout sections of pipeworks.

Why Choose Videray for NDT?

As the NDT industry evolves, Videray leads with innovation, delivering safer, faster, and more effective handheld X-ray solutions. Reduce downtime, enhance inspection efficiency, and achieve precise, non-invasive material analysis with Videray’s advanced imaging technology.